Page 9 - Cabinetry-Comparison

P. 9

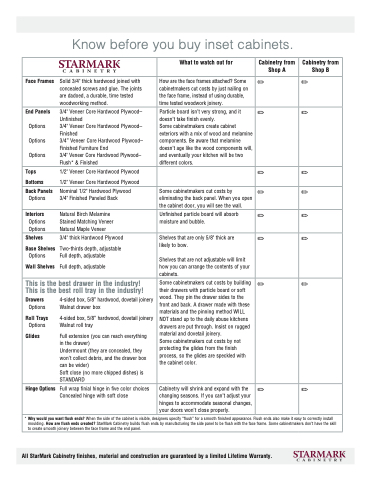

Know before you buy inset cabinets.

What to watch out for

Cabinetry from Shop A

Cabinetry from Shop B

Face Frames Solid 3/4" thick hardwood joined with concealed screws and glue. The joints

are dadoed, a durable, time tested woodworking method.

How are the face frames attached? Some cabinetmakers cut costs by just nailing on the face frame, instead of using durable, time tested woodwork joinery.

✏

✏

End Panels

Options Options Options

3/4" Veneer Core Hardwood Plywood– Unfinished

3/4" Veneer Core Hardwood Plywood– Finished

3/4” Veneer Core Hardwood Plywood– Finished Furniture End

3/4" Veneer Core Hardwood Plywood– Flush* & Finished

Particle board isn’t very strong, and it doesn’t take finish evenly.

Some cabinetmakers create cabinet exteriors with a mix of wood and melamine components. Be aware that melamine doesn’t age like the wood components will, and eventually your kitchen will be two different colors.

✏

✏

Tops 1/2" Veneer Core Hardwood Plywood Bottoms 1/2" Veneer Core Hardwood Plywood

✏

✏

Back Panels Nominal 1/2" Hardwood Plywood Options 3/4" Finished Paneled Back

Some cabinetmakers cut costs by eliminating the back panel. When you open the cabinet door, you will see the wall.

✏

✏

Interiors

Options Options

Natural Birch Melamine Stained Matching Veneer Natural Maple Veneer

Unfinished particle board will absorb moisture and bubble.

✏

✏

Shelves Base Shelves

Options

Wall Shelves

3/4" thick Hardwood Plywood

Two-thirds depth, adjustable Full depth, adjustable

Full depth, adjustable

Shelves that are only 5/8" thick are likely to bow.

Shelves that are not adjustable will limit how you can arrange the contents of your cabinets.

✏

✏

This is the best drawer in the industry! This is the best roll tray in the industry!

Drawers

Options

Roll Trays

Options

Glides

4-sided box, 5/8” hardwood, dovetail joinery Walnut drawer box

4-sided box, 5/8” hardwood, dovetail joinery Walnut roll tray

Full extension (you can reach everything in the drawer)

Undermount (they are concealed, they won’t collect debris, and the drawer box can be wider)

Soft close (no more chipped dishes) is STANDARD

Some cabinetmakers cut costs by building their drawers with particle board or soft wood. They pin the drawer sides to the front and back. A drawer made with these materials and the pinning method WILL NOT stand up to the daily abuse kitchens drawers are put through. Insist on rugged material and dovetail joinery.

Some cabinetmakers cut costs by not protecting the glides from the finish process, so the glides are speckled with the cabinet color.

✏

✏

Hinge Options Full wrap finial hinge in five color choices Concealed hinge with soft close

Cabinetry will shrink and expand with the changing seasons. If you can’t adjust your hinges to accommodate seasonal changes, your doors won’t close properly.

✏

✏

* Why would you want flush ends? When the side of the cabinet is visible, designers specify “flush” for a smooth finished appearance. Flush ends also make it easy to correctly install moulding. How are flush ends created? StarMark Cabinetry builds flush ends by manufacturing the side panel to be flush with the face frame. Some cabinetmakers don’t have the skill to create smooth joinery between the face frame and the end panel.

All StarMark Cabinetry finishes, material and construction are guaranteed by a limited Lifetime Warranty.